One of mine client has been experiencing problem with his printing process and was suspected that fabrication involving some wood product in an adjacent unit high be affecting his prints. He has sent me some filters taken out of his printing machine for microscopic analysis. The purpose of the investigation was to investigate the nature of the dust accumulated on the filters. Fours samples in total were submitted for investigation, a clean filter, and contaminated filter, small section of MDF and polymer residue. The submitted filters were UV Lamp filters type A60179-A used in printing machines.

Samples of dust particles were collected from the filter using micro vacuum method. The dust was collected onto 25mm nitrocellulose filters. The filters were mounted onto microscope slides and cleared by acetone vapour under high temperature. The prepared slides were examined by means of phase contrast optical microscopy under 500 and 1250 magnification.

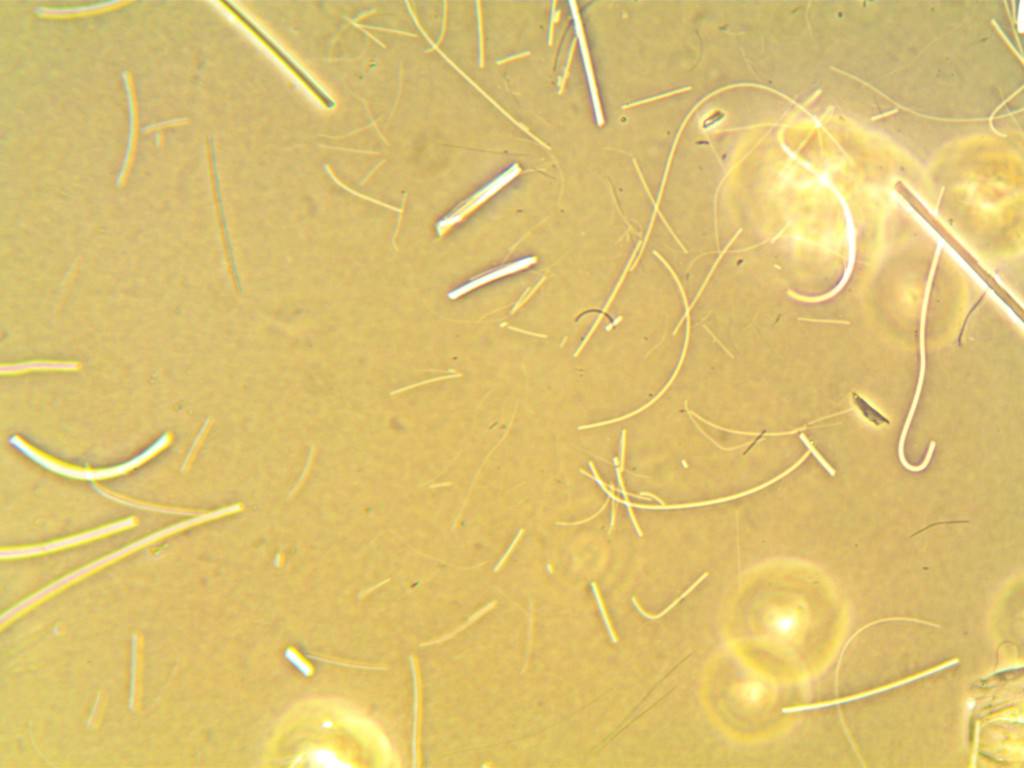

To start the investigation I have firstly examined the unspoiled filter to get a picture of the king of particles, dust and fibres normally present on the filters of this type. The microscopic examination shows the presence of curved, maybe, synthetic fibres, straight, most likely, mineral glass fibres and a small number of anamorphous particles with both low and high opacity.

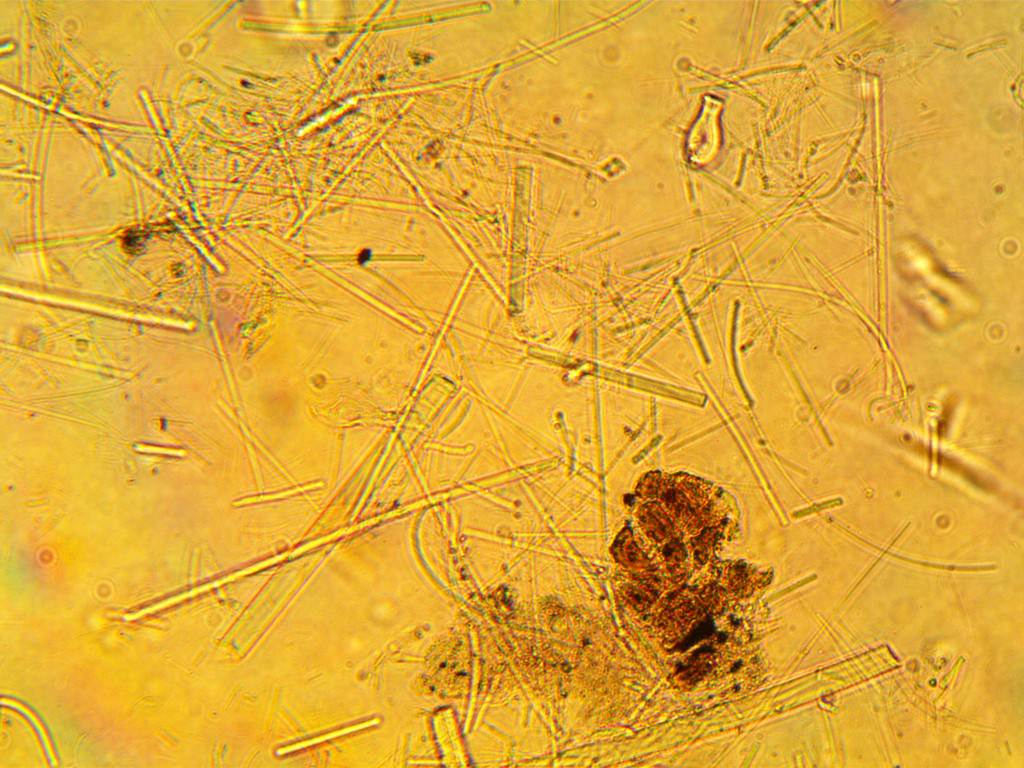

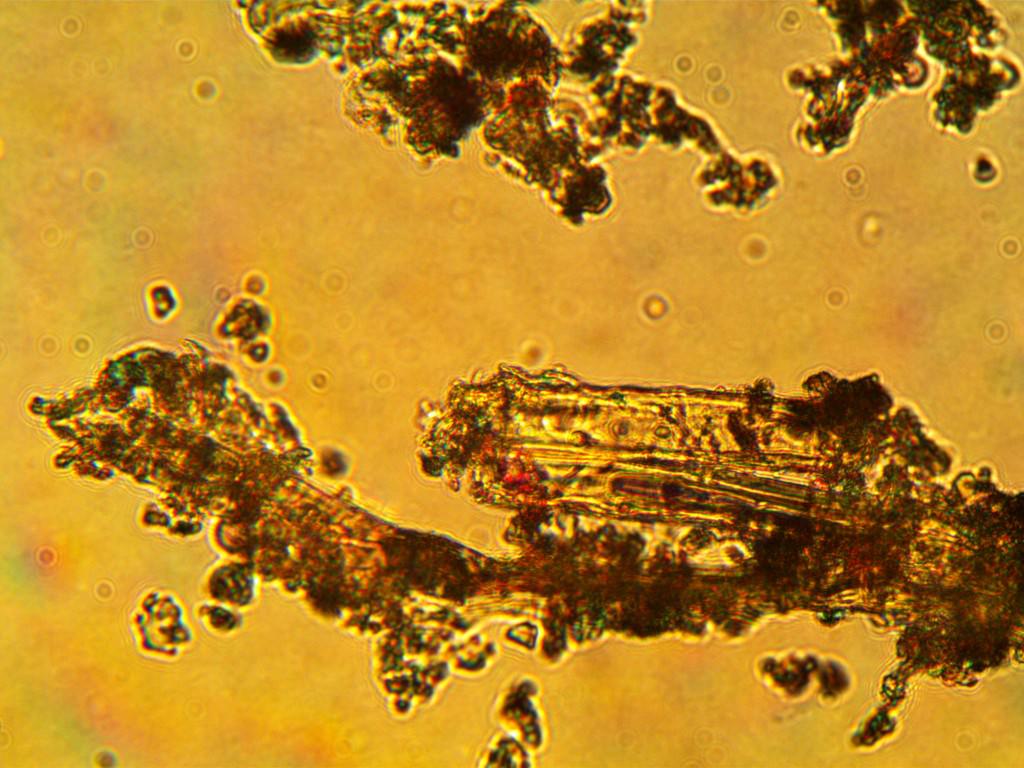

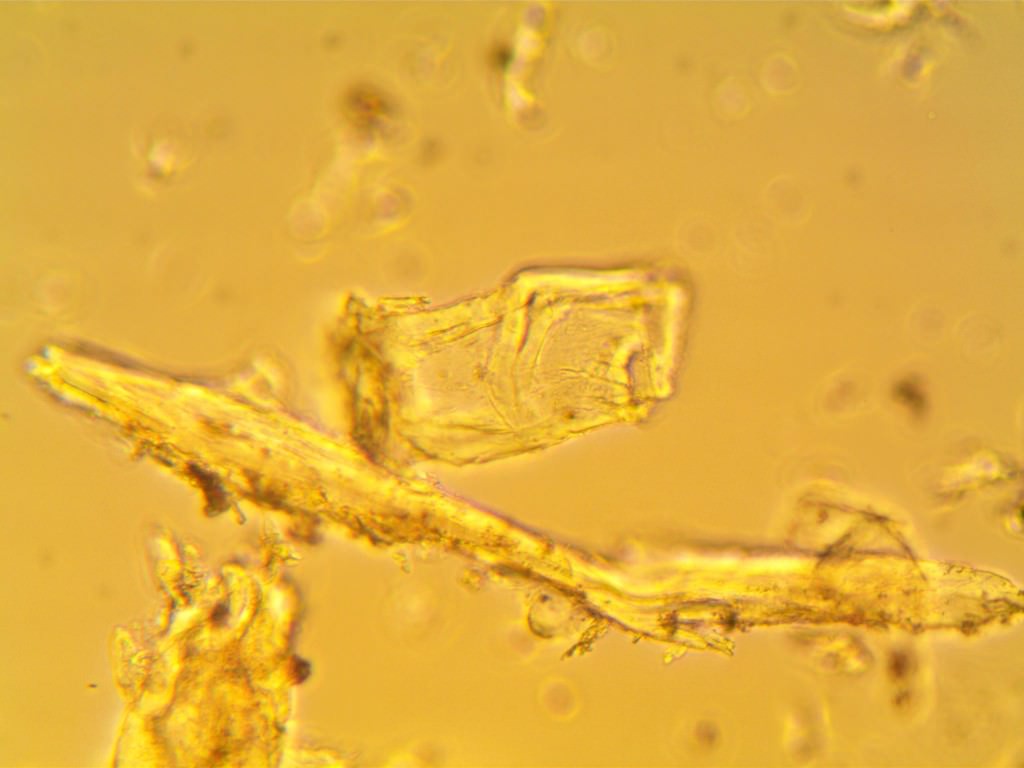

Then I have examined the two possible source materials. The MDF (medium density particle board) dust sample was obtained by abrasion of the MDF surface with a scalpel. Microscopic examination shows the presence of large anamorphous agglomerates formed by adhesion of larger translucent homogenous particles and small high opacity particles. The morphological characteristics of wood fibres can be clearly observed on the larger particles. Smaller fragments are translucent with clean elongated edges generally angular in shape.

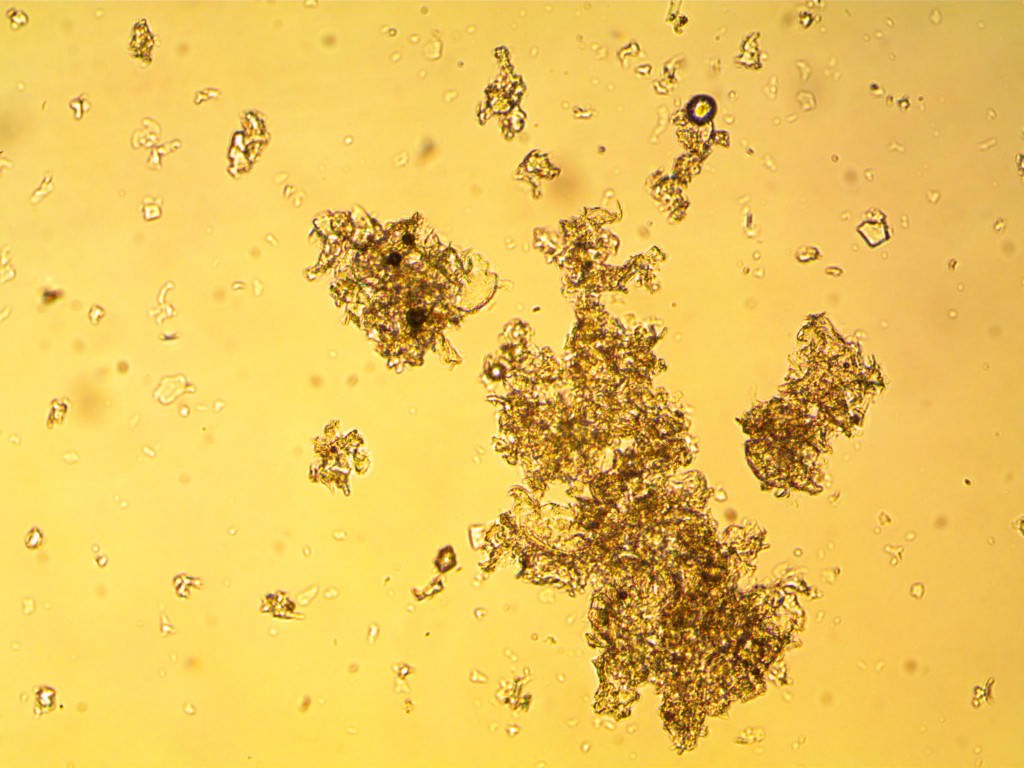

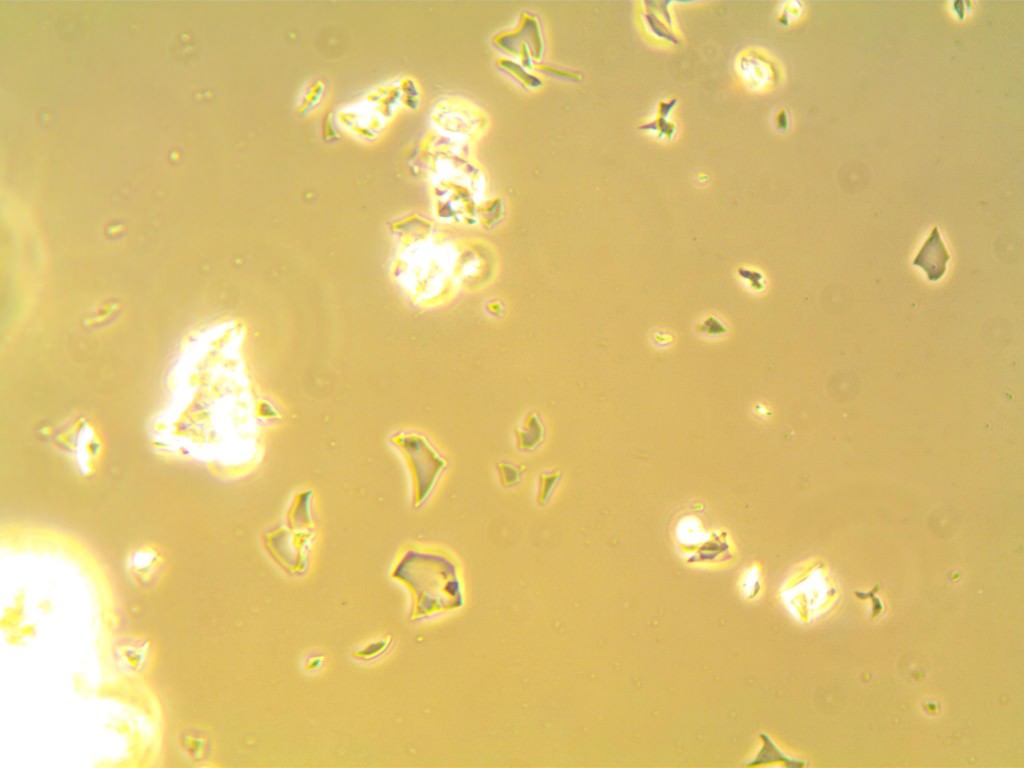

The second possible source sample consists of a polymer residue. The sample was obtained by abrasion of the polymer surface with a scalpel. Microscopic examination shows that the polymer tends to form relatively large loosely bound anamorphous particles of low opacity. At high magnification the polymer particles liberated from larger agglomerates can be described as, flake like, translucent with slightly grey hue and smooth elongated edges.

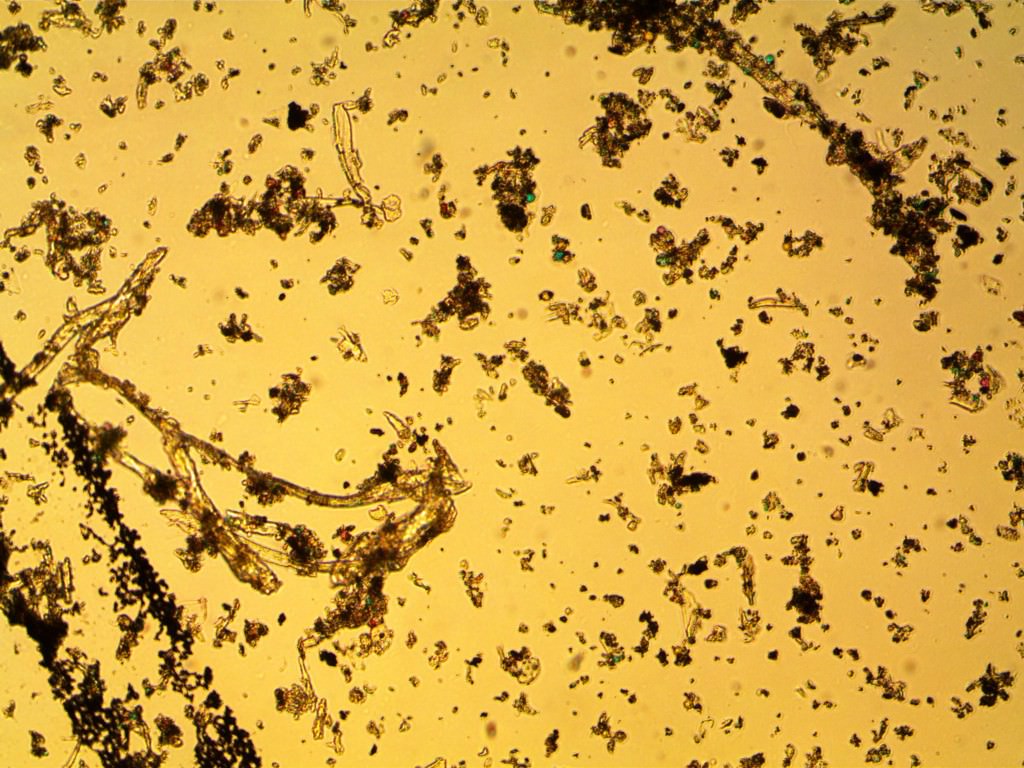

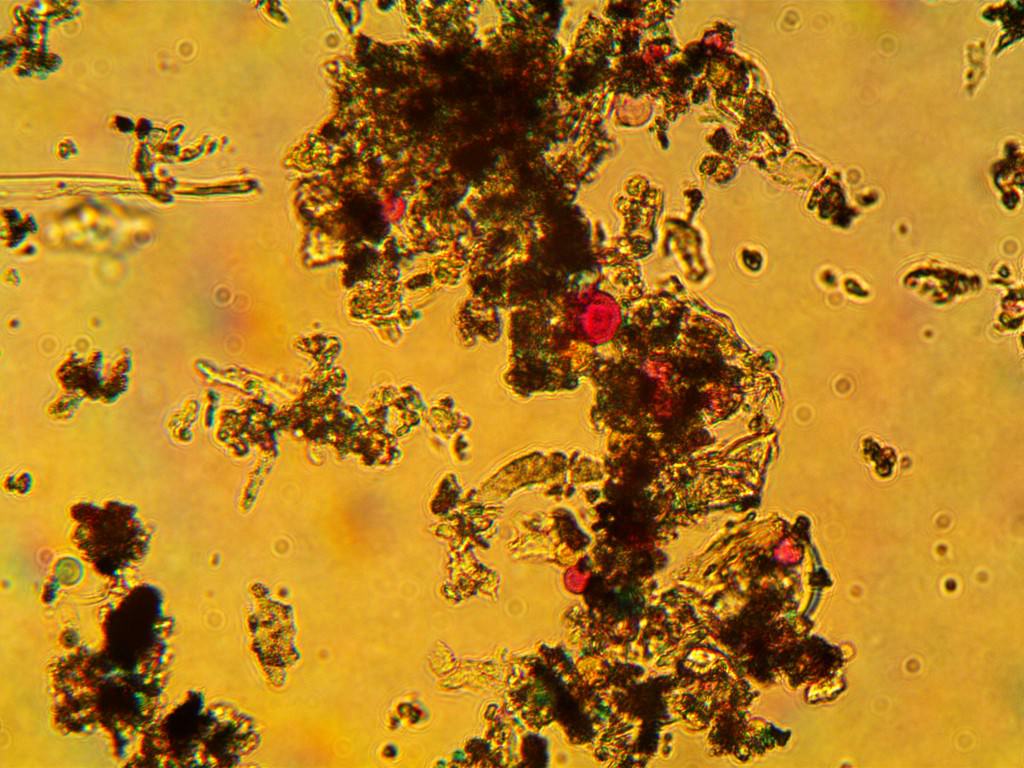

As the last I have examined the used filter sample taken from a loosely bound synthetic fibre filter which has been removed from the machines after unspecified time of operation. The samples show much more significant accumulation of dust particles. The large particles are anamorphous with some morphological characteristics consistent with wood fibres. The sample contains a relatively large number of anamorphous high opacity particles mixed with elongated curved and twisted synthetic fibres. Colour ink aerosol particles can be observed and red and blue globules attached to the larger particles.

Microscopic examination of the submitted samples and subsequent comparison between the used filter samples and suspected source materials confirm the presence of wood dust particles accumulate don the filter materials. Other particles observed on the filter included long, curved, flat and translucent fibres mostly likely originated from the paper; Small high opacity anamorphous particles most likely consisting of environmental dust and/or dark inks; brightly coloured globular aerosols particles most likely originating from colour inks. The presence of polymer like particles was not confirmed, however high temperature environment in close proximity to the UV lamp is likely to have a significant effect on polymer particles. It is likely that some of the high opacity anamorphous particles are temperature fused polymer dust.

By Tomas Gabor